Products & Services

Labels

Apparel labels are an essential role in today’s supply chain. Not only do they promote brand recognition, communicate important consumer information such as size and care instructions, but they also help protect against theft and counterfeiting.

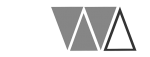

As our starting point in the industry, we consider ourselves pioneers in the department of label manufacturing. With 09 printing machines available, Weera Industries is capable of producing 600000-700000 lables per day at full capacity. The 10 cutting machines can accommodate jobs to be cold cut, hot cut or ultrasonically cut, while the labels can be finished as straight cut, centre fold, end fold or mitre fold. Our goal is to assure fast and good quality delivery for all orders undertaken and hence there is no minimum order quantity.

We print on a range of materials including Polyester Satin, Nylon Taffeta, Cotton Tape, Twill Tape, Acetate Satin, Poly Cotton, Self Adhesive Satin, Woven-Edged Satin.

The complete process of design to finishing takes place under one roof assures that the whole production is under observation of the QA team at different levels.

With the achievement of the OEKO-TEX standard 100, we offer human ecological safe textiles for our product range.

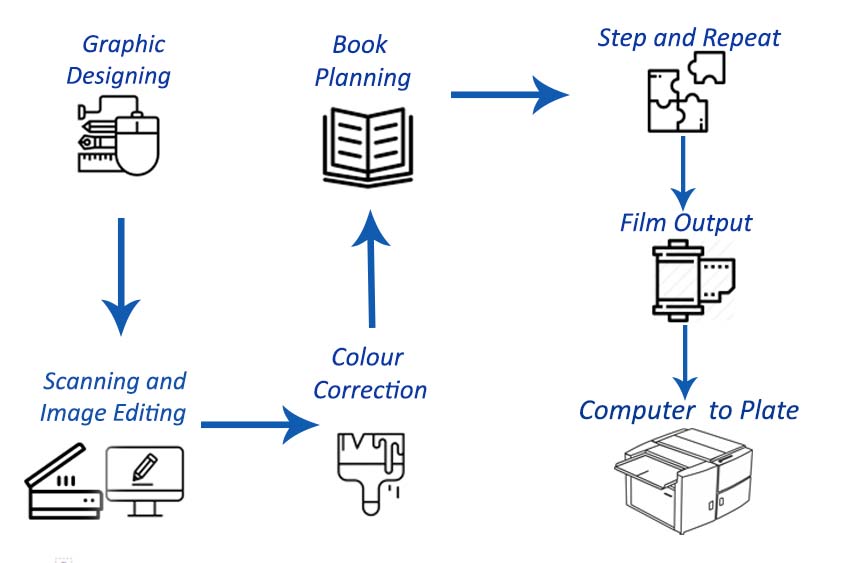

Pre-Press Solutions

Since 2004, Weera Industries offers complete Prepress Service of high quality, giving value for money. Our services include:

Graphic Designing

Any great printing begins with great design. Our skilled graphic designers at Weera Industries offers in-house graphic designing services that help the customer visualise the image they would want for their brand.

Scanning and Image Editing

We are equipped with high-end scanners that when combined with a meticulously regulated computer monitor can re-produce images in high quality. The capacity also handles scanning of transparencies and slides.

Colour Correction

Used to rectify problems in colour quality and tonal range in images for high-quality catalogues, brochures, and magazines by our trained specialists that are equipped with a comprehensive set of tools.

Book Planning

Whether it be perfect bound, centre wired, section bound or any other special finish, Weera Industries’ prepress specialists are trained to cater to all client requirements.

Step and Repeat

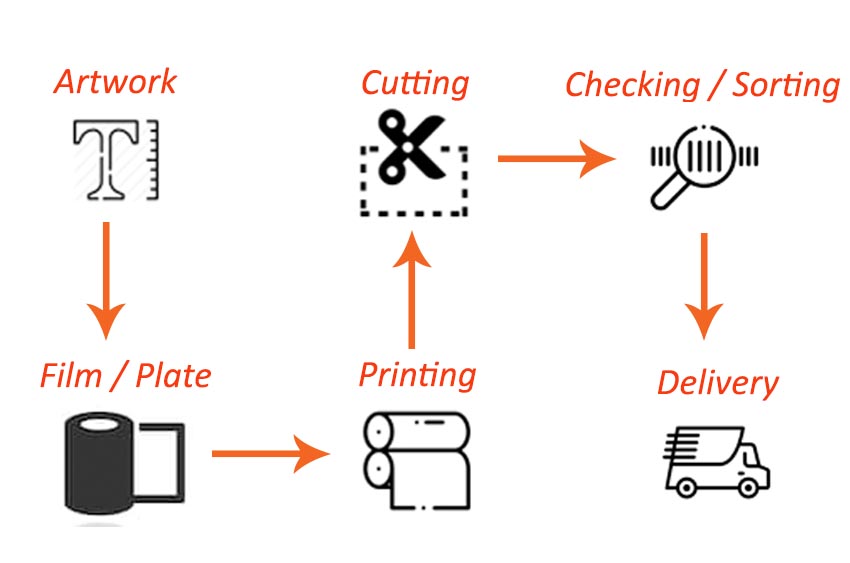

Step and repeat is the procedure for multiplying the placement of the same image on plates/film done using Industry standard software, which assures high accuracy and best usage of material.

Film Output

Our state of the art image setters that are equipped with regular calibration, usage of quality branded films and chemicals and our in-house quality system that assures the highest quality of output of positives and negatives.

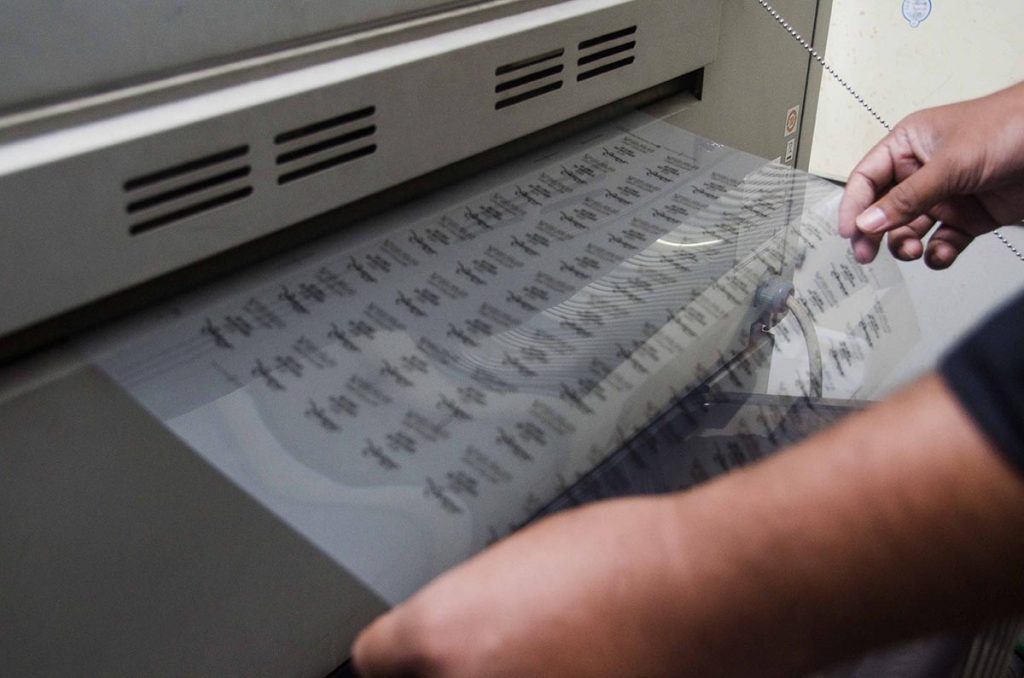

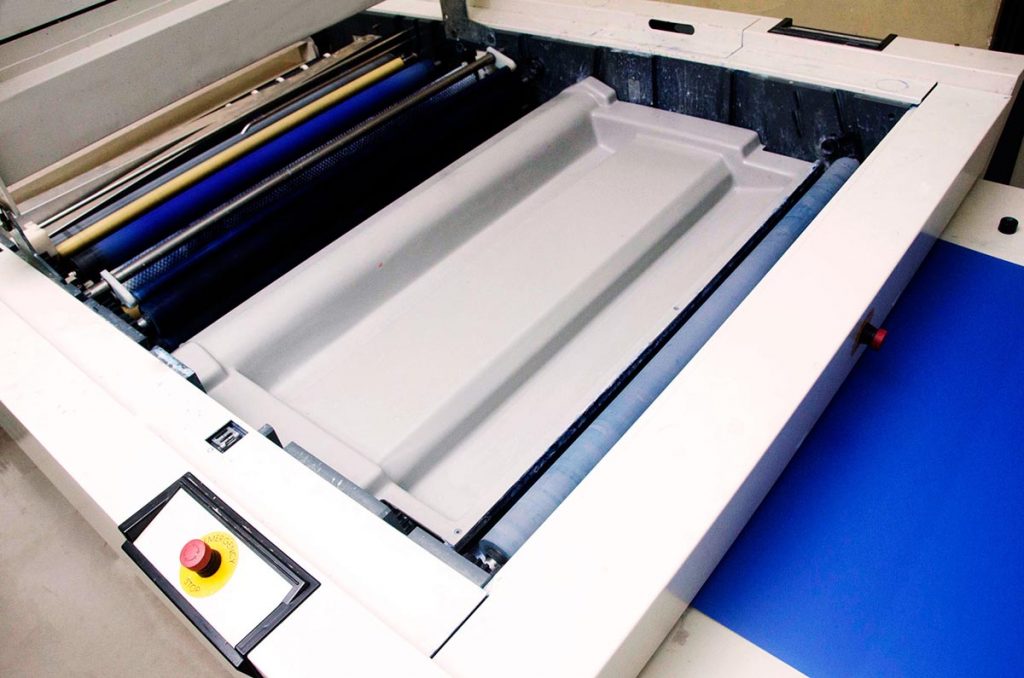

Computer to Plate

Our Computer to Plate ensures that the latest technology in offset printing is available to all. This digital form of plate making helps printers achieve a quality that is unparalleled to an average press.

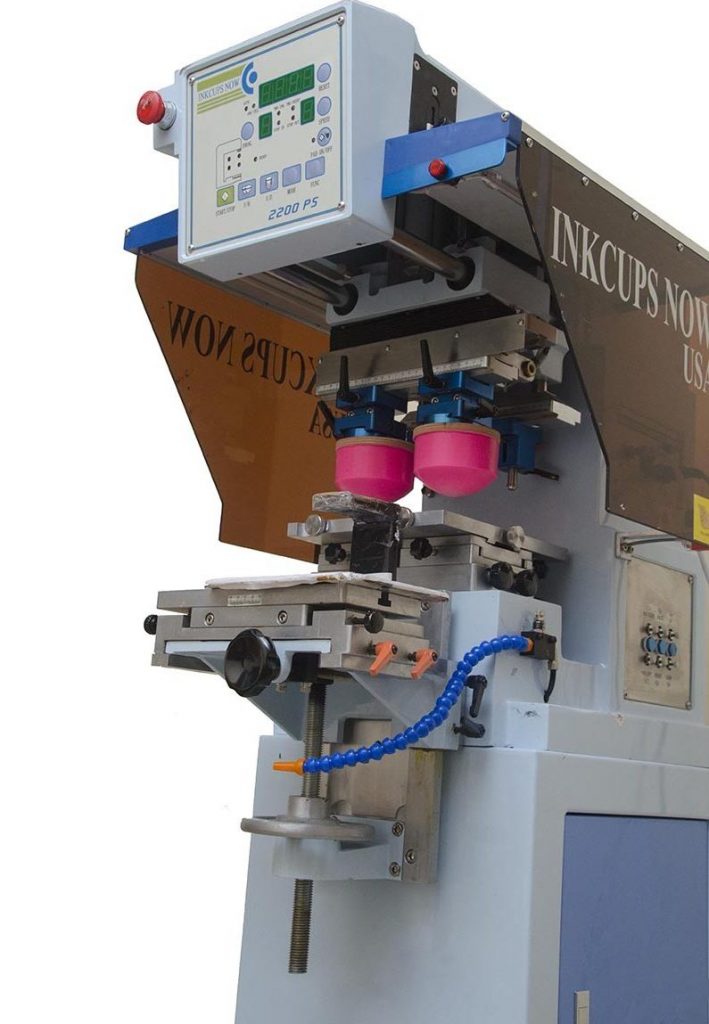

Tagless / Pad Printing

Inkcups Now: Tagless Pad Printing is the newest evolution in garment tag labelling and most cost-effective and flexible alternative to heat transfer labels.

With Tagless Pad Printing, printing of labels can be done directly onto apparel from underwear and shape-wear to active wear and outerwear.

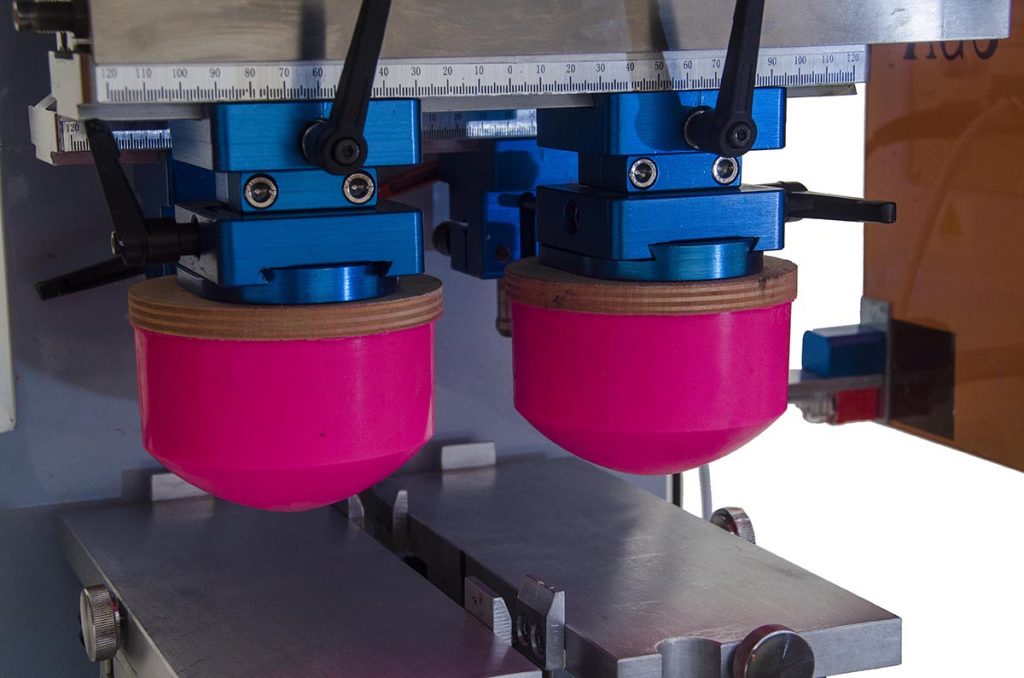

Pad Printers

Designed for industrial use, each pad printer is fast, easy to operate and features an ink resistant ink cup, tagless tooling fixture and optional garment alignment laser.

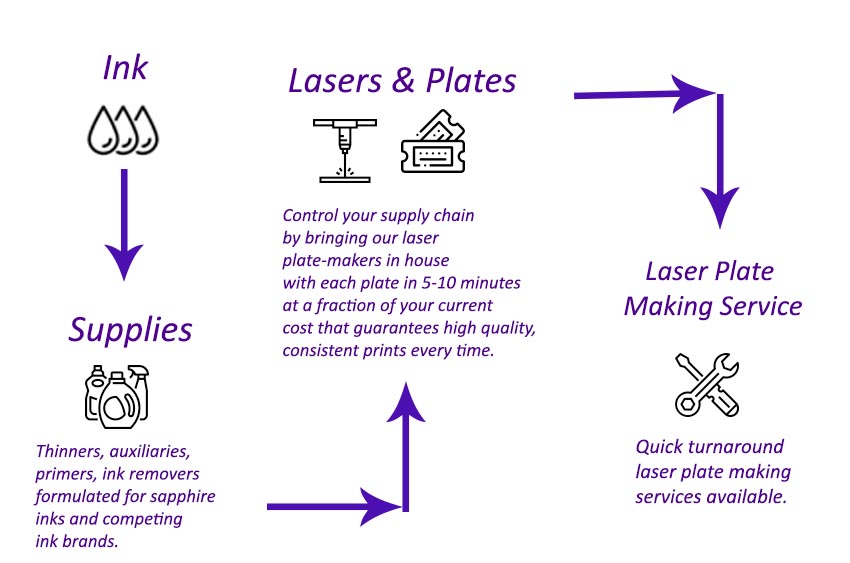

Ink

The highest quality inks are fully compliant with international standards and specially manufactured for tagless printing.

Supplies

Thinners, auxiliaries, primers, ink removers formulated for sapphire inks and competing ink brands.

Lasers And Plates

Control your supply chain by bringing our laser plate-makers in house with each plate in 5-10 minutes at a fraction of your current cost that guarantees high quality, consistent prints every time.